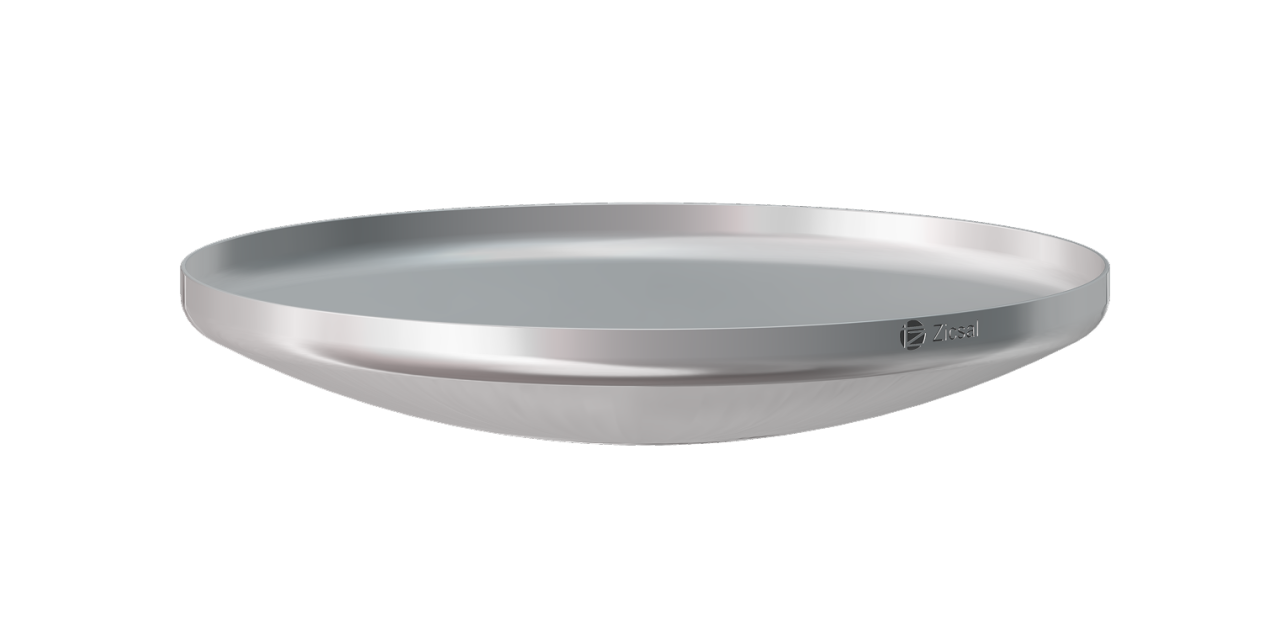

Quality

Since 1966, at ZICSAL we have perfected our processes to offer

high-precision, safe and certified industrial solutions. We ensure that

every dished head, shell, or component meets the highest industry

standards. Our commitment to quality is also reflected in the

continuous training of our technical team.

We believe that a highly qualified workforce ensures safety at work,

fosters innovation, and drives professional growth within the

company. That is why we have certifications that guarantee the

quality of our processes and products, in full compliance with the

highest international standards.

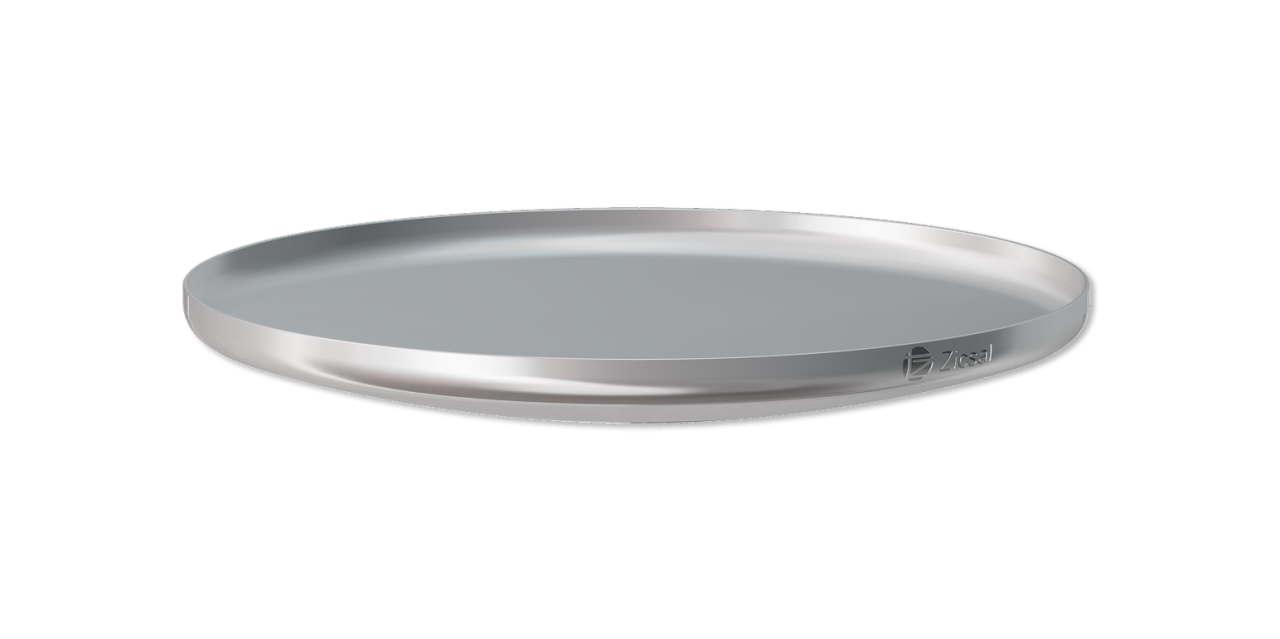

Quality control and non-destructive testing

Quality is the cornerstone of our manufacturing process. At ZICSAL, we apply rigorous controls at every stage of the production process

to ensure that each component meets the most demanding technical

and regulatory requirements.

These tests allow us to guarantee the safety and reliability of each

part, ensuring compliance with international standards.

Technical documentation delivered with

every order.

To guarantee the quality and transparency, we provide standardized

technical documentation with all orders. Additionally, we offer

extended reports upon request, adapting to the specific

requirements of each customer.

Included as standard with all orders:

Always included

- Dimensional inspection

- Base material certificate

Available upon request

- Dye penetrant testing

- Ultrasonic testing

- Magnetic particle testing

- Surface roughness report

- Heat treatment report

- Forming procedure

- Radiographic testing

- Welding qualifications

- Welder approvals

- Filler material certificate

Certificates that back up our work

Our certifications ensure that our processes comply with the strictest

national and international standards. We ensure that all welding

personnel are certified and qualified to manufacture industrial

dished heads within our facilities.